Composite Strap: A Versatile Option for Load Securement and Safety

In the dynamic world of logistics, transportation, and industrial handling, the significance of secure and reliable load restraint cannot be overstated. Ensuring that goods remain intact and in place during transit is crucial for minimizing damage, reducing losses, and maintaining operational efficiency. Among the various materials and techniques employed for load securement, composite straps have emerged as a versatile and increasingly popular option. This article delves into the multifaceted advantages of composite straps, their diverse applications, and their pivotal role in enhancing load security and safety.

The Evolution of Load Securement Solutions

Historically, load restraint methods have ranged from traditional ropes and chains to more modern synthetic materials like polypropylene and polyester straps. Each material offers unique benefits but also presents certain limitations in terms of strength, durability, flexibility, and environmental impact. Composite straps represent a significant advancement in this field, combining the strengths of multiple materials to create a high-performance, adaptable solution.

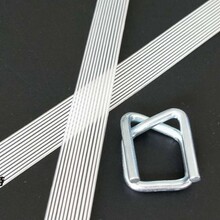

What Are Composite Straps?

Composite straps are designed using a blend of materials, reinforced with additional materials to enhance their mechanical properties. The composite nature of these straps allows for tailored strength, stiffness, and weight, making them suitable for a wide range of applications. They often feature a protective coating or cover to improve abrasion resistance and weatherproofing, ensuring longevity and performance in harsh environments.

Versatility in Applications

One of the key strengths of composite straps lies in their versatility. Whether securing pallets, crates, or heavy machinery, composite straps offer a reliable and often cost-effective alternative to traditional restraint methods. Their lightweight nature facilitates easier handling and reduces fuel consumption during transportation. The ability to customize strap length, width, and breaking strength according to specific requirements ensures that composite straps can be tailored to fit any load configuration.

In the packaging industry, composite straps are valued for their ability to securely bundle products while minimizing packaging waste. Their flexibility allows for tight, uniform tensioning, reducing the risk of shifting and damage. In aerospace and automotive sectors, where precision and lightweight materials are crucial, composite straps offer unparalleled strength-to-weight ratios, contributing to fuel efficiency and operational safety.

Enhancing Load Security

Composite straps excel in providing secure load restraint, thanks to their high tensile strength and resilience under stress. They are designed to withstand the rigors of transit, including vibration, shock, and changes in temperature. This robust performance helps prevent loads from shifting, which can lead to collisions, overloading, and potential accidents. The elastic recovery of composite straps also means they maintain tension over time, reducing slack and maintaining secure restraint throughout the journey.

Safety First

Beyond their load-bearing capabilities, composite straps prioritize safety. Their design often incorporates features such as tear-resistant weaves, color-coded strength indicators, and easy-to-use tensioning and release mechanisms. These features enhance operator safety by minimizing the risk of strap failure and facilitating quicker, safer application and removal. Composite straps are also less prone to causing injury compared to metal straps or chains, which can cause cuts or punctures if mishandled.

Environmental Considerations

In today's conscious market, environmental impact is a significant consideration in material selection. Composite straps offer an eco-friendly alternative to traditional materials. Many are made from recycled synthetic fibers, and some can be recycled themselves at the end of their useful life. Their lightweight nature reduces fuel consumption and carbon emissions associated with transportation. Furthermore, the durability of composite straps means they can be reused multiple times, contributing to a more sustainable supply chain.

Innovations and Future Trends

The future of composite straps looks promising, with ongoing research and development driving innovations in material science and manufacturing processes. Smart composite straps, incorporating sensors and RFID technology, are emerging to provide real-time monitoring of load conditions, further enhancing safety and operational efficiency. The integration of biodegradable materials and improved recycling processes will also address environmental concerns, positioning composite straps as a forward-thinking solution.

Conclusion

Composite straps have revolutionized load securement and safety across various industries. Their versatility, strength, and eco-friendly attributes make them an invaluable asset in modern logistics and industrial handling. As technology advances and the focus on sustainability intensifies, composite straps will continue to evolve, offering even greater performance and environmental benefits. For businesses seeking reliable, adaptable, and efficient load restraint solutions, composite straps are a clear choice for the future.