Enhancing Load Security with Heavy Duty Woven Strapping Solutions

In today's fast-paced logistics and transportation world, ensuring the safety and security of goods in transit is paramount. Heavy-duty woven strapping solutions have emerged as a reliable and cost-effective means to enhance load security, offering unparalleled strength, durability, and versatility. This article explores the various aspects of heavy-duty woven strapping and how it can be utilized to safeguard cargo during transportation.

Introduction to Heavy Duty Woven Strapping

Heavy-duty woven strapping, often referred to as polypropylene woven strapping or polypropylene webbing, is a robust material designed to secure heavy loads. It is made from high-tensile polypropylene fibers that are woven into a strong, flexible, and lightweight strap. This material is renowned for its excellent tensile strength, resistance to abrasion and cutting, and its ability to withstand extreme temperatures.

Advantages of Heavy Duty Woven Strapping

1.Strength and Durability: Heavy-duty woven strapping is renowned for its exceptional strength and durability. It can withstand significant tensile forces, ensuring that loads remain securely fastened during transportation. Additionally, its abrasion-resistant properties allow it to withstand the rigors of handling and shipping, minimizing the risk of damage or failure.

2.Flexibility: Unlike traditional metal strapping, heavy-duty woven strapping is highly flexible. This allows it to conform to irregularly shaped loads, providing a more secure and even distribution of tension across the entire package.

3.Lightweight: Despite its strength, heavy-duty woven strapping is significantly lighter than metal strapping. This reduces the overall weight of the load, which can lead to cost savings in terms of transportation and handling.

4.Ease of Use: Heavy-duty woven strapping is easy to apply and remove, often requiring only simple tools or even manual tensioning. This improves efficiency and reduces the risk of operator error.

5.Environmentally Friendly: Polypropylene, the primary material used in heavy-duty woven strapping, is recyclable and has a lower environmental impact compared to some other packaging materials.

Applications of Heavy Duty Woven Strapping

Heavy-duty woven strapping finds widespread applications in various industries, including but not limited to:

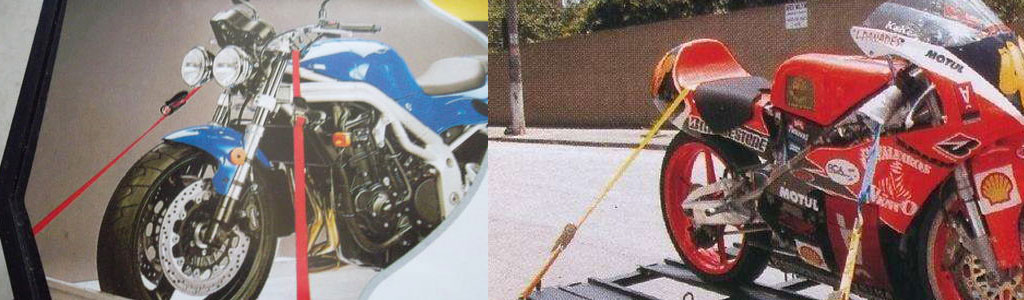

1.Logistics and Transportation: In the logistics and transportation industry, heavy-duty woven strapping is used to secure pallets, crates, and other types of cargo. It ensures that loads remain stable and secure during shipment, reducing the risk of damage or loss.

2.Packaging and Warehousing: In packaging and warehousing operations, heavy-duty woven strapping is used to bundle and secure products for storage or distribution. It provides a cost-effective and reliable means of keeping items organized and protected.

3.Manufacturing: In manufacturing environments, heavy-duty woven strapping is used to secure components and assemblies during production or shipping. It helps ensure that products arrive at their destination intact and ready for use.

4.Agriculture: In the agricultural sector, heavy-duty woven strapping is used to bundle crops, such as hay or straw, for easy handling and transportation. It also finds applications in securing tarpaulins and other protective covers on agricultural equipment.

Best Practices for Using Heavy Duty Woven Strapping

To ensure maximum load security with heavy-duty woven strapping, it is important to follow a few best practices:

1.Select the Appropriate Size and Type: Choose a strapping size and type that is suitable for the weight and dimensions of your load. Consider factors such as tensile strength, width, and thickness to ensure adequate security.

2.Properly Apply and Tighten: Apply the strapping evenly and tightly across the load, ensuring that there are no loose or sagging areas. Use the appropriate tensioning tool to achieve the desired tension level.

3.Inspect Regularly: Regularly inspect the strapping for signs of wear, damage, or loosening. Replace any worn or damaged strapping immediately to maintain load security.

4.Follow Safety Guidelines: Always follow the safety guidelines provided by the manufacturer when handling and applying heavy-duty woven strapping. This includes wearing appropriate protective equipment and avoiding excessive tensioning or cutting.

In conclusion, heavy-duty woven strapping offers a reliable and cost-effective solution for enhancing load security in various industries. Its strength, durability, flexibility, and ease of use make it an ideal choice for securing heavy loads during transportation and storage. By following best practices and selecting the appropriate strapping for your needs, you can ensure that your cargo arrives safely and securely at its destination.