Exploring the Versatility of Polyester Strapping

Introduction

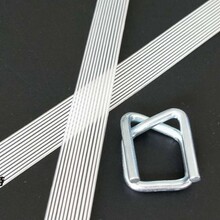

Polyester strapping, also known as PET strapping, has become an increasingly popular choice for binding various materials in industries such as packaging, transportation, and construction. This versatile material offers several advantages over traditional strapping materials like steel and polypropylene, making it an attractive alternative for businesses looking to reduce costs and increase efficiency. In this article, we will delve into the world of polyester strapping, exploring its properties, applications, and the reasons behind its growing popularity.

Properties of Polyester Strapping

Polyester strapping is made from polyethylene terephthalate (PET), a strong and durable plastic polymer. Some of the key properties of polyester strapping include:

1. High tensile strength: Polyester strapping has a high tensile strength, which means it can withstand heavy loads without breaking or stretching.

2. Weather resistance: PET is resistant to moisture, UV radiation, and other environmental factors, making polyester strapping suitable for outdoor applications.

3. Lightweight: Polyester strapping is lightweight compared to steel strapping, making it easier to handle and reducing transportation costs.

4. Flexibility: Polyester strapping is flexible, allowing it to conform to the shape of the bundled items, reducing the risk of damage during transportation.

5. Easy to use: Polyester strapping is easy to use with various strapping tools, and it can be easily tensioned and sealed.

Applications of Polyester Strapping

The versatility of polyester strapping makes it suitable for a wide range of applications, including:

1. Packaging: Polyester strapping is commonly used to bundle and secure boxes, pallets, and other packaged goods for transportation.

2. Construction: Polyester strapping is used to secure building materials, such as timber and steel, during transportation and construction.

3. Shipping: Polyester strapping is used to secure shipping containers and pallets, ensuring the safe and secure transportation of goods.

4. Manufacturing: Polyester strapping is used in various manufacturing processes to bundle and secure materials during transportation and storage.

Advantages of Polyester Strapping

1. Cost-effectiveness: Polyester strapping is generally less expensive than steel strapping, making it a cost-effective option for businesses.

2. Eco-friendly: Polyester strapping is recyclable and produces less waste than steel strapping, making it a more environmentally friendly option.

3. Ease of use: Polyester strapping is easier to use than steel strapping, reducing the risk of injuries and improving efficiency.

4. Durability: Polyester strapping has a longer lifespan than steel strapping, reducing replacement costs and increasing overall efficiency.

Conclusion

Polyester strapping has emerged as a versatile and efficient alternative to traditional strapping materials. Its high tensile strength, weather resistance, lightweight, flexibility, and ease of use make it an attractive choice for businesses looking to reduce costs and increase efficiency. As environmental concerns continue to grow, the recyclability and eco-friendliness of polyester strapping make it an even more compelling option for businesses looking to reduce their environmental impact.