Hot Melt Strapping in Waste Compactors: A Comprehensive Guide

In the realm of waste management, efficient and reliable packaging solutions are paramount to ensuring safe and secure transportation of waste materials. Among these solutions, Hot Melt Strapping stands out as a versatile and highly effective choice, particularly in waste compactors. This article delves into the intricacies of Hot Melt Strapping, its unique features, and its indispensable role in waste compression processes.

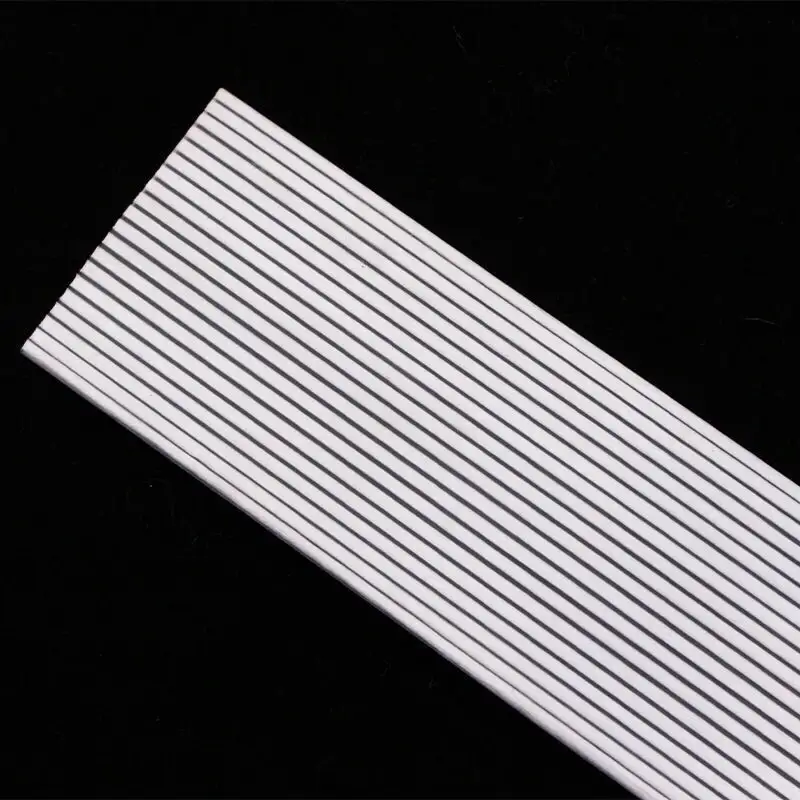

Introduction to Hot Melt Strapping

Hot Melt Strapping, also known as hot melt polyester strapping, is a specialized form of packaging material that utilizes heat to activate its adhesive properties. Unlike traditional steel or plastic strapping, Hot Melt Strapping combines the strength of polyester fibers with the adhesion capabilities of a heat-activated glue. This unique combination results in a strong, flexible, and lightweight strapping solution that is ideally suited for a wide range of applications, including waste compression.

Key Features of Hot Melt Strapping

1.Strength and Durability: Hot Melt Strapping boasts exceptional tensile strength, ensuring that waste materials are securely bound during compression. Its polyester core provides a robust foundation, while the heat-activated glue creates a strong bond that resists breaking under pressure.

2.Flexibility: The material's flexibility allows it to conform to the irregular shapes and contours of compressed waste, ensuring a tight and secure fit. This adaptability is crucial in waste compactors, where waste materials are compressed into dense, irregularly shaped blocks.

3.Lightweight: Compared to steel strapping, Hot Melt Strapping is significantly lighter, making it easier to handle and transport. This reduced weight also translates to cost savings in terms of fuel consumption and transportation fees.

4.Heat Resistance: The heat-activated glue used in Hot Melt Strapping is designed to withstand high temperatures, making it suitable for use in waste compactors that generate significant amounts of heat during the compression process.

5.Environmental Friendliness: As a recyclable material, Hot Melt Strapping contributes to a more sustainable waste management system. Its polyester composition can be easily separated from the waste stream for recycling, reducing the environmental impact of waste disposal.

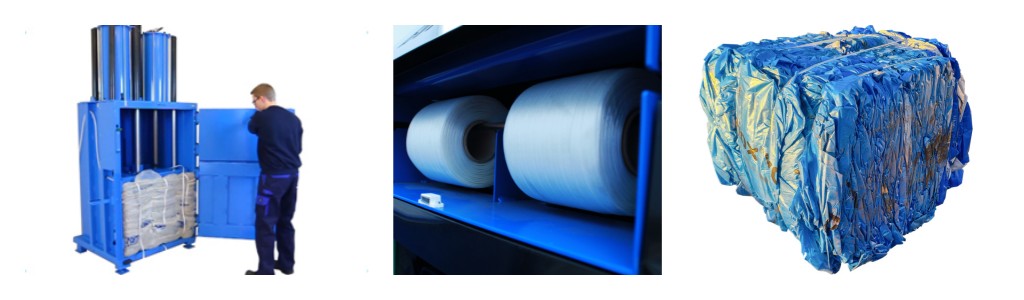

Application in Waste Compactors

In waste compactors, Hot Melt Strapping plays a vital role in securing compressed waste blocks for transportation and disposal. The following steps outline the process of using Hot Melt Strapping in waste compression:

1.Compression: Waste materials are fed into the compactor, where they are compressed into dense blocks. This process reduces the volume of waste, making it easier to handle and transport.

2.Strapping Preparation: As the compressed waste blocks emerge from the compactor, they are ready for strapping. Hot Melt Strapping is fed through a dispenser or applicator, which applies a controlled amount of heat to activate the glue.

3.Application: The heated Hot Melt Strapping is wrapped around the compressed waste block, creating a tight and secure seal. The heat-activated glue bonds instantly to the waste material, ensuring that the block remains intact during transportation.

4.Cutting and Finishing: Once the desired number of wraps have been applied, the Hot Melt Strapping is cut to length, leaving a neat and professional finish. The resulting waste block is now ready for transportation to a disposal facility.

Advantages of Using Hot Melt Strapping in Waste Compactors

1.Increased Efficiency: The use of Hot Melt Strapping streamlines the waste compression process, reducing the time and effort required to secure compressed waste blocks.

2.Cost Savings: The lightweight nature of Hot Melt Strapping results in cost savings in terms of transportation and handling. Additionally, its recyclability contributes to a more sustainable waste management system, which can lead to long-term cost savings.

3.Improved Safety: By securely binding compressed waste blocks, Hot Melt Strapping reduces the risk of waste spillage during transportation. This, in turn, minimizes the potential for accidents and injuries.

4.Environmental Benefits: As a recyclable material, Hot Melt Strapping supports sustainable waste management practices. Its use in waste compactors contributes to a more environmentally friendly approach to waste disposal.

Conclusion

In conclusion, Hot Melt Strapping is a highly effective and versatile packaging solution that plays a crucial role in waste compression processes. Its unique combination of strength, flexibility, and heat resistance makes it ideally suited for use in waste compactors. By securely binding compressed waste blocks, Hot Melt Strapping streamlines the waste management process, reduces costs, and contributes to a more sustainable waste disposal system. As the demand for efficient and environmentally friendly waste management solutions continues to grow, Hot Melt Strapping is poised to play an increasingly important role in the waste compression industry.