Plant Fiber Strap: The Preferred Alternative to PP and PET Strap

In the realm of packaging and bundling solutions, innovation has always been driven by the pursuit of sustainability, efficiency, and environmental responsibility. Among these advancements, plant fiber strap has emerged as a groundbreaking material, redefining the standards for eco-friendly and cost-effective packaging alternatives. This article delves into why plant fiber strap has become the preferred choice over traditional polypropylene (PP) and polyethylene terephthalate (PET) straps, highlighting its unique advantages and the pivotal role it plays in promoting a greener future.

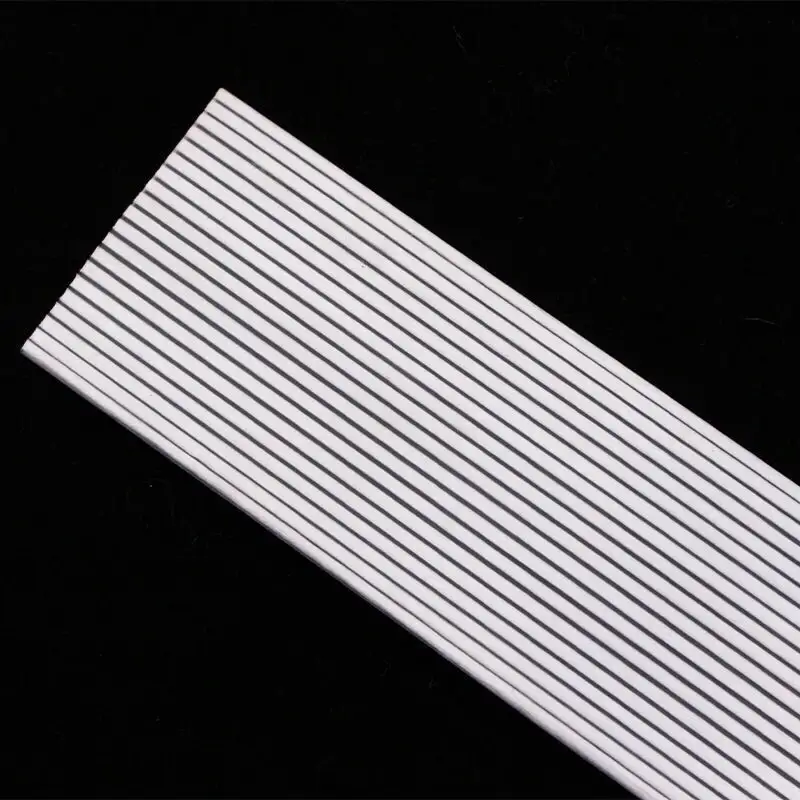

Introduction to Plant Fiber Strap

Plant fiber strap, as the name suggests, is a composite material crafted from natural plant fibers intertwined with a biodegradable adhesive. This innovative product leverages the abundance and renewability of plant-based resources, such as bamboo, hemp, and agricultural residues, to create a robust and environmentally friendly packaging solution. By harnessing the strength and versatility of these natural fibers, plant fiber strap offers a sustainable alternative to the conventional PP and PET straps that have dominated the market for decades.

Sustainability: The Core Advantage

At the heart of plant fiber strap's appeal lies its unparalleled sustainability. Unlike PP and PET, which are derived from non-renewable fossil fuels, plant fiber strap relies on a virtually inexhaustible source of raw materials. The plants used in its production not only regenerate quickly but also sequester carbon dioxide during their growth cycle, contributing to the mitigation of climate change. Furthermore, upon disposal, plant fiber strap can be easily composted or biodegraded, returning nutrients to the soil and minimizing the burden on landfills and incineration facilities. This closed-loop approach to packaging aligns perfectly with the global push towards circular economy and zero-waste initiatives.

Environmental Impact Reduction

The environmental footprint of plant fiber strap is significantly lower than that of PP and PET straps. The production of these synthetic materials involves energy-intensive processes that emit greenhouse gases and potentially harmful byproducts. In contrast, the manufacturing of plant fiber strap requires less energy and generates fewer emissions, making it a more environmentally conscious choice. Moreover, the biodegradability of plant fiber strap eliminates the risk of long-term pollution associated with non-biodegradable plastics, safeguarding ecosystems and ensuring a healthier planet for future generations.

Economic Benefits and Cost-Effectiveness

While the initial investment in plant fiber strap might seem higher than that of PP and PET straps, the long-term economic benefits far outweigh the upfront costs. The lower raw material costs, coupled with the potential for cost savings in waste management and compliance with environmental regulations, make plant fiber strap a financially viable option. As consumer awareness of sustainable products grows, businesses that adopt plant fiber strap can also benefit from enhanced brand reputation and customer loyalty, further boosting their bottom line.

Performance Parity and Versatility

Contrary to popular misconceptions, plant fiber strap is not just an environmentally friendly novelty; it is a high-performance material that rivals and often surpasses the capabilities of PP and PET straps. Modern manufacturing techniques have refined the strength, durability, and resilience of plant fiber strap, making it suitable for a wide range of applications, including heavy-duty bundling, shipping, and logistics. Its resistance to moisture, chemicals, and UV radiation ensures reliable performance in diverse environmental conditions, making it an ideal choice for both indoor and outdoor use.

Policy Support and Market Trends

The global shift towards sustainability is evident in the numerous policies and regulations being enacted by governments worldwide. Many countries have implemented bans or taxes on single-use plastics, including PP and PET packaging materials, incentivizing businesses to adopt eco-friendly alternatives. This policy landscape, coupled with the growing consumer preference for sustainable products, creates a favorable market environment for plant fiber strap. As awareness of its benefits spreads, the demand for plant fiber strap is expected to soar, driving innovation and further advancements in the field.

Conclusion

In conclusion, plant fiber strap stands as a testament to the power of innovation in addressing the pressing challenges of sustainability and environmental protection. Its unique combination of eco-friendliness, cost-effectiveness, and high performance makes it the preferred alternative to PP and PET straps. As businesses and consumers alike embrace the need for greener solutions, plant fiber strap is poised to revolutionize the packaging industry, leading the way towards a more sustainable and resilient future.