Polyester Composite Straps: The Ultimate Solution for Durable and Lightweight Applications

In today’s fast-paced industrial landscape, the demand for reliable and efficient materials is at an all-time high. Among these materials, polyester composite straps have emerged as a premier choice for a variety of applications, from packaging and shipping to construction and manufacturing. This article explores the properties, advantages, and diverse applications of polyester composite straps, highlighting why they are considered the ultimate solution for durable and lightweight needs.

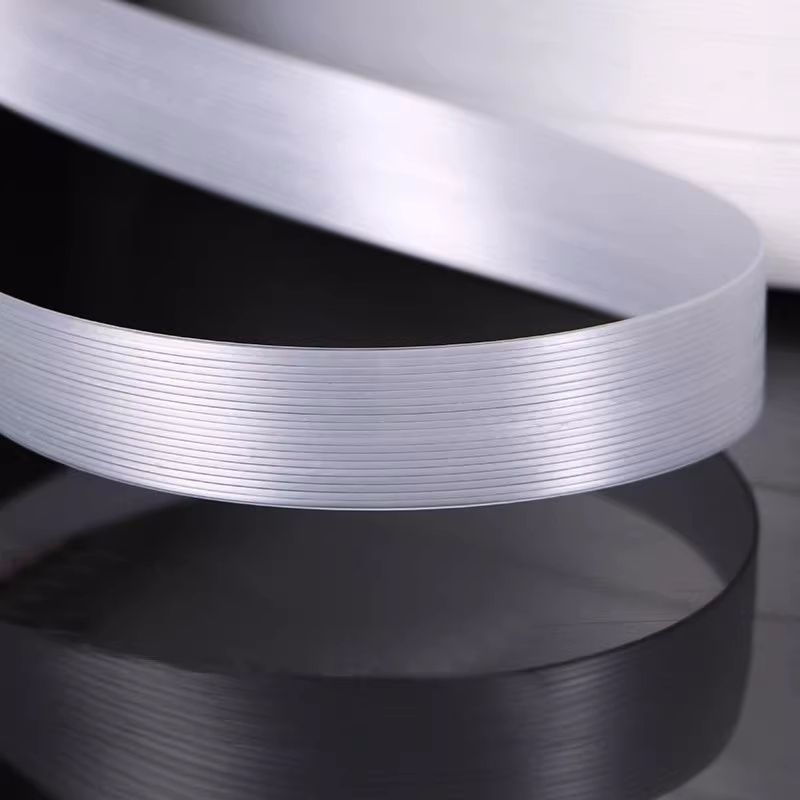

What Are Polyester Composite Straps?

Polyester composite straps are made from high-strength polyester fibers, often blended with other materials to enhance their performance. These straps are known for their exceptional tensile strength, flexibility, and resistance to various environmental factors. This unique combination of properties makes them ideal for a wide range of applications that require both durability and lightweight characteristics.

Key Properties of Polyester Composite Straps

1. High Tensile Strength: One of the most significant advantages of polyester composite straps is their high tensile strength. They can withstand substantial loads without breaking, making them suitable for securing heavy goods during transport or in construction.

2. Lightweight: Unlike metal straps, polyester composite straps are lightweight, which significantly reduces shipping costs and makes handling easier. This weight efficiency is a crucial factor in logistics and packaging, where reducing overall weight can lead to savings.

3. Flexibility: Polyester composite straps are highly flexible, allowing them to conform to various shapes and sizes. This adaptability makes them easier to work with compared to more rigid materials like metal.

4. Resistance to Environmental Factors: These straps are resistant to UV rays, moisture, and chemicals, which helps prevent degradation over time. This durability is particularly beneficial for outdoor applications where exposure to the elements is inevitable.

5. Non-Corrosive: Unlike metal straps, which can rust and corrode, polyester composite straps do not have these vulnerabilities. This characteristic extends the lifespan of the straps and ensures consistent performance in challenging environments.

Advantages of Using Polyester Composite Straps

1. Cost-Effectiveness

While the initial investment in polyester composite straps may be higher than that of traditional materials, their long-term benefits outweigh the upfront costs. Their durability leads to reduced replacement and maintenance expenses, making them a cost-effective choice over time. Businesses can save money on logistics and material handling due to the straps' lightweight nature.

2. Versatility

Polyester composite straps are incredibly versatile, finding applications in a range of industries, including logistics, automotive, construction, and even agriculture. Their ability to adapt to various requirements makes them suitable for different tasks, from securing goods for transport to providing structural support in construction.

3. Enhanced Safety

The strength and reliability of polyester composite straps enhance safety in operations. When securing loads, the risk of breakage is significantly reduced compared to using weaker materials. This added safety is crucial in industries where load integrity is paramount, such as shipping and construction.

4. Ease of Use

Polyester composite straps are user-friendly. They can be easily cut to length and applied without the need for specialized tools. This ease of use streamlines operations, allowing workers to focus on productivity rather than struggling with complicated fastening mechanisms.

5. Environmental Considerations

While polyester is derived from petrochemical sources, many manufacturers are increasingly exploring recycling options for polyester materials. This initiative aligns with the growing emphasis on sustainability in manufacturing and packaging, making polyester composite straps a more environmentally responsible choice compared to some traditional synthetic materials.

Applications of Polyester Composite Straps

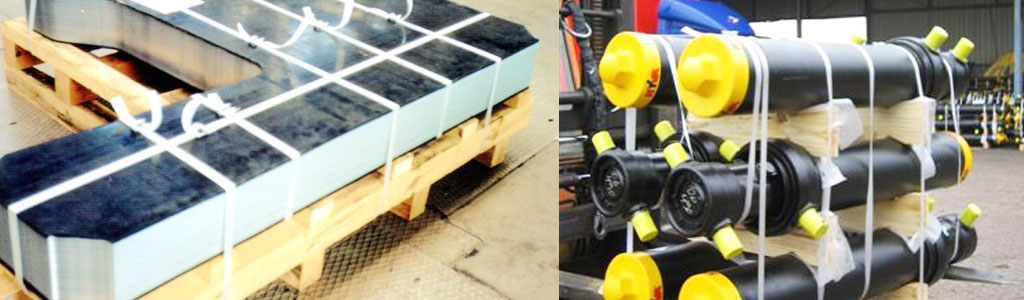

1. Logistics and Packaging

In logistics, the ability to securely package and transport goods is essential. Polyester composite straps are commonly used for palletizing, bundling, and securing products during shipping. Their lightweight and high-strength properties ensure that goods remain intact throughout the transportation process.

2. Construction

In construction, polyester composite straps are utilized for various purposes, such as bracing and stabilizing structures. Their resistance to environmental factors makes them suitable for outdoor applications, providing reliable support without the risk of rust or corrosion.

3. Automotive Industry

The automotive industry benefits from polyester composite straps for transporting parts and components. Their strength and flexibility make them ideal for securing irregularly shaped items, ensuring safe and efficient transport.

4. Agriculture

In agriculture, polyester composite straps are used for bundling hay, securing pallets of produce, and other agricultural products. Their resistance to moisture and UV exposure makes them an excellent choice for outdoor use.

5. Electrical and Electronics

Polyester composite straps are also finding applications in the electrical and electronics industries for bundling cables and securing components during transport. Their lightweight nature ensures that they do not add unnecessary weight to delicate items.

Conclusion

Polyester composite straps stand out as the ultimate solution for durable and lightweight applications across various industries. Their combination of high tensile strength, flexibility, and resistance to environmental factors makes them a superior choice over traditional materials. As industries continue to prioritize efficiency and safety, the demand for polyester composite straps is likely to grow, making them a staple in the toolkit of modern manufacturers, shippers, and constructors. By embracing this innovative material, businesses can enhance their operational efficiency, reduce costs, and ensure the integrity of their products throughout the supply chain.