Sustainable Solutions: Woven Strapping for Eco-Friendly Waste Management

In today's rapidly evolving world, the importance of sustainable waste management practices cannot be overstated. With the increasing emphasis on environmental conservation and resource efficiency, businesses are exploring innovative solutions to streamline their waste management processes while minimizing their ecological footprint. One such solution that has gained traction in the industry is the use of woven strapping for waste compaction, particularly in the handling of cardboard materials.

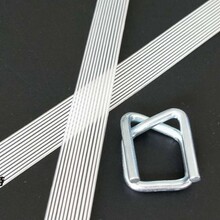

Woven strapping, also known as woven polyester strapping, offers a durable and versatile alternative to traditional strapping materials such as steel or plastic. Made from high-quality polyester fibers woven together to form a strong and flexible band, woven strapping is ideally suited for securing and bundling compressed materials in waste compactors, particularly in cardboard baler systems. Its unique construction provides excellent tensile strength and resistance to elongation, making it an ideal choice for applications that require secure and reliable strapping.

One of the key advantages of using woven strapping in waste compaction is its sustainability and eco-friendliness. Unlike traditional strapping materials that are derived from non-renewable resources or pose environmental hazards, woven polyester strapping is made from recycled polyester fibers or can be recycled after use, making it a more environmentally responsible choice. By opting for woven strapping, businesses can reduce their carbon footprint and contribute to the circular economy by promoting the reuse and recycling of materials.

Furthermore, the use of woven strapping in waste compaction systems can lead to significant cost savings for businesses. The durable nature of woven polyester strapping ensures long-lasting performance, reducing the frequency of replacement and maintenance costs associated with traditional strapping materials. Additionally, the superior strength and reliability of woven strapping minimize the risk of product damage or loss during transportation, further enhancing operational efficiency and reducing financial losses.

In addition to its sustainability and cost-effectiveness, woven strapping offers a range of performance benefits that make it an ideal choice for waste management applications. The flexibility and elasticity of woven polyester strapping allow for secure and tight bundling of materials, preventing shifting or loosening during compaction and transportation. This ensures that compressed waste materials remain intact and organized, optimizing the efficiency of waste compaction processes and reducing the volume of waste generated.

Moreover, the high tensile strength of woven strapping makes it suitable for securing heavy or bulky materials, such as compressed cardboard, without compromising on safety or reliability. The woven structure of the strapping distributes tension evenly across the material, minimizing the risk of breakage or slippage during handling or transportation. This enhances workplace safety and reduces the likelihood of accidents or injuries associated with improperly secured materials.

In conclusion, woven strapping represents a sustainable and effective solution for eco-friendly waste management in businesses and industries that generate significant volumes of cardboard waste. By harnessing the durability, reliability, and environmental benefits of woven polyester strapping, organizations can enhance the efficiency, safety, and cost-effectiveness of their waste compaction operations. As the demand for sustainable waste management practices continues to grow, woven strapping emerges as a valuable tool for promoting environmental stewardship and resource conservation in the modern business landscape.