The Essentials of Hot Melt Baler Strapping in Packaging and Shipping

In the world of packaging and shipping, the use of hot melt baler strapping has become an integral part of the process, ensuring the security and stability of goods during transportation. This technology, which combines the power of hot melt adhesives with the efficiency of automatic strapping machines, has revolutionized the way we secure packages, pallets, and other shipping units.

The Fundamentals of Hot Melt Baler Strapping

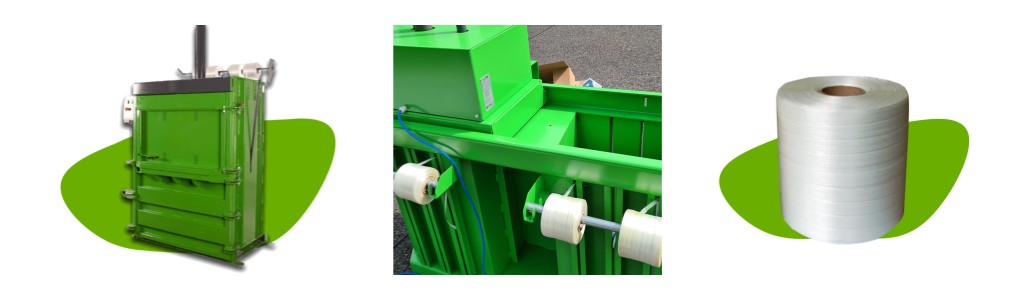

Hot melt baler strapping involves the application of a hot melt adhesive tape or strap to a package or pallet. This adhesive, when heated to a specific temperature, becomes malleable and able to adhere strongly to the surface of the package. Once applied, the adhesive cools quickly, solidifying and forming a strong bond that secures the package in place.

The process begins with the operator feeding the adhesive strap into the baler machine. The machine then heats the strap to the required temperature, melts the adhesive, and applies it to the package. The adhesive is typically applied in a continuous strip, wrapping around the package and securing it in place. The machine automatically tightens the strap and cuts it off, completing the strapping process.

Advantages of Hot Melt Baler Strapping

There are numerous advantages to using hot melt baler strapping in packaging and shipping applications. One of the most significant benefits is the strength and durability of the adhesive bond. Hot melt adhesives form a strong, permanent bond with the package surface, providing superior security and stability during transportation. This reduces the risk of packages shifting or becoming damaged during handling and shipping.

Another advantage of hot melt baler strapping is its efficiency. The automatic baler machines are designed to quickly and accurately apply the adhesive strap to packages, significantly reducing the time and labor required for manual strapping. This increased efficiency not only saves money but also helps meet the demands of high-volume shipping operations.

Hot melt baler strapping is also versatile and can be used on a wide range of package types and sizes. The adhesive strap can be adjusted to fit different package dimensions, and the machines can be configured to handle various materials, including cardboard, plastic, and metal. This flexibility allows hot melt baler strapping to be used in a variety of packaging and shipping applications.

Challenges and Considerations

While hot melt baler strapping offers many benefits, there are also some challenges and considerations to take into account. One of the main challenges is the need for specialized equipment and training. The baler machines require proper maintenance and calibration to ensure they function effectively. Operators also need to be trained on how to use the machines safely and efficiently.

Additionally, the adhesive strap itself can be affected by temperature and humidity conditions. If the adhesive is not heated to the correct temperature or if the environment is too humid, the bond may not be as strong as desired. It is important to monitor and adjust the machine settings to ensure the adhesive is applied properly in all conditions.

Environmental Impact and Sustainable Practices

As the packaging industry continues to evolve, there is an increasing focus on sustainable practices and reducing the impact on the environment. Hot melt baler strapping offers some environmental benefits compared to traditional strapping methods. The adhesive strap is typically made from recyclable materials, and the machines can be designed to minimize waste and energy consumption.

However, there are still opportunities for improvement. Manufacturers are exploring ways to develop more environmentally friendly adhesives that have lower emissions and biodegradability. Additionally, innovative packaging designs and strategies can reduce the overall need for strapping, further reducing the impact on the environment.

Conclusion

In conclusion, hot melt baler strapping is a powerful and efficient tool for securing packages and pallets during shipping. Its strong adhesive bond, versatility, and efficiency make it an ideal choice for a wide range of packaging and shipping applications. While there are some challenges and considerations to take into account, the environmental benefits and opportunities for improvement make hot melt baler strapping a viable solution for the future of sustainable packaging.