The Importance and Applications of Woven Lashing Straps

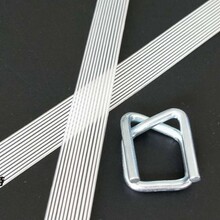

In the realm of industrial packaging and securing, woven lashing straps have become an essential tool for ensuring the safety and stability of cargo during transportation. These straps, made from woven materials such as polyester or polypropylene, offer a robust and reliable solution for tying down loads of various sizes and weights.

The Fundamentals of Woven Lashing Straps

Woven lashing straps are designed to withstand the rigors of transportation, whether by land, sea, or air. Their woven construction provides a high degree of flexibility while maintaining sufficient strength to secure even the heaviest loads. The materials used in their manufacture are chosen for their durability, strength-to-weight ratio, and resistance to wear and tear.

The process of weaving the straps involves interlacing threads in a specific pattern to create a strong yet pliable structure. This process ensures that the straps maintain their integrity under tension and are able to conform to the contours of the cargo they are securing.

Applications of Woven Lashing Straps

The versatility of woven lashing straps makes them suitable for a wide range of applications. In the shipping industry, they are commonly used to secure containers on ships and in cargo holds. Their ability to conform to irregular shapes and withstand the movement of cargo during voyages ensures that containers remain tightly bound and unlikely to shift or topple over.

In the logistics and transportation sector, woven lashing straps are invaluable for securing pallets, crates, and other types of cargo on trucks and trailers. They are easily adjustable, allowing operators to quickly and securely tie down loads of varying sizes and shapes. This flexibility makes them ideal for use in warehouses, distribution centers, and other facilities where cargo needs to be moved efficiently and safely.

In addition to their use in the shipping and logistics industries, woven lashing straps also find applications in the construction sector. They are often used to secure building materials, such as lumber, steel beams, and concrete blocks, during transportation to construction sites. Their strength and durability ensure that these materials arrive at their destination in good condition and ready for use.

Advantages of Woven Lashing Straps

There are several advantages that make woven lashing straps a preferred choice for securing cargo. One of the key advantages is their strength-to-weight ratio. Woven straps are able to support heavy loads while remaining lightweight, making them easy to handle and transport. This is especially important in applications where weight savings are crucial, such as in aircraft cargo holds.

Another advantage of woven lashing straps is their flexibility. Unlike rigid metal straps or chains, woven straps can conform to the contours of the cargo they are securing. This ensures that the straps provide a uniform and secure hold, reducing the risk of damage to the cargo or the straps themselves.

Furthermore, woven lashing straps are resistant to wear and tear. They are able to withstand the abrasion and friction that can occur during transportation, maintaining their integrity and strength over extended periods of use. This durability makes them a cost-effective solution for long-term use in demanding environments.

Environmental Considerations

In today's increasingly environmentally conscious world, the sustainability of materials and products is an important consideration. Woven lashing straps are often made from recyclable materials such as polyester or polypropylene, reducing the environmental impact of their production and disposal. Additionally, their durability and longevity contribute to their overall sustainability, as they require less frequent replacement and disposal compared to less durable alternatives.

Conclusion

In conclusion, woven lashing straps play a crucial role in ensuring the safety and stability of cargo during transportation. Their strength, flexibility, durability, and environmental sustainability make them a preferred choice for securing loads in a wide range of applications. As the demand for safe and efficient cargo securing solutions continues to grow, woven lashing straps are likely to remain an essential tool in the logistics and transportation industries.