The Indispensable Role of Baler Strapping in Modern Packaging and Logistics

In the vast and intricate landscape of modern packaging and logistics, baler strapping stands as a cornerstone in ensuring the safe, secure, and efficient transportation of goods from one end of the supply chain to another. This vital element, often overlooked amidst the grandeur of high-tech automation and advanced materials, plays a pivotal role in maintaining the integrity of packages, minimizing damage, and optimizing storage space. This article delves into the intricacies of baler strapping, exploring its significance, types, applications, and the technological advancements that have revolutionized its use in today's fast-paced industry.

Introduction

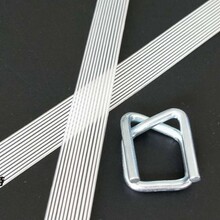

Baler strapping, simply put, refers to the process of using straps or bands to secure, bundle, and compress goods within a baler machine. These machines are designed to automate the packaging process, compressing loose materials or products into compact, manageable units, which are then secured with strapping materials. The purpose of this process is multifaceted: it enhances product protection, facilitates easier handling and stacking, and optimizes shipping costs by maximizing the use of available space.

Applications Across Industries

Baler strapping is ubiquitous across various industries, each with its unique packaging requirements:

-Retail and E-commerce: With the surge in online shopping, baler strapping has become crucial in preparing parcels for shipment. It ensures that individual items or boxed products are securely bundled, reducing the risk of damage during transit.

-Food and Beverage: In the food industry, baler strapping helps maintain hygiene standards by securely sealing pallets of perishables, preventing contamination and ensuring freshness.

-Manufacturing: From automotive parts to industrial equipment, baler strapping is used to compress and bundle raw materials, work-in-progress, and finished goods, facilitating efficient storage and transportation.

-Textiles and Apparel: In the textile sector, large rolls of fabric or bundled garments are often compressed and strapped to save space and protect against damage during shipment.

-Waste Management: Recyclables and waste materials are often baled and strapped for efficient collection and transportation, reducing the environmental footprint of waste disposal.

Technological Advancements

The world of baler strapping has witnessed significant technological advancements in recent years, driving efficiency, safety, and sustainability:

-Automation and Robotics: The integration of automation and robotics into baling and strapping processes has drastically reduced manual labor, increasing productivity and accuracy.

-Intelligent Sensing and Control Systems: Advanced sensors and control systems enable precise tensioning and real-time monitoring of the strapping process, ensuring optimal security and minimizing material waste.

-Eco-Friendly Materials: The growing emphasis on sustainability has led to the development of eco-friendly strapping materials, such as biodegradable and recycled plastics, reducing the environmental impact of packaging waste.

-Data Integration: With the rise of Industry 4.0, baler strapping machines are now capable of integrating with enterprise resource planning (ERP) systems, providing real-time data on packaging performance and inventory management.

Conclusion

Baler strapping, while seemingly unassuming, is a vital component in the intricate machinery of modern packaging and logistics. Its ability to securely compress and bundle goods, combined with the advancements in technology and materials, has made it an indispensable tool in ensuring the safe and efficient movement of products across the globe. As the industry continues to evolve, baler strapping will play an increasingly critical role in meeting the challenges of the future, including sustainability, automation, and the ever-growing demands of e-commerce. In this context, the importance of continuous innovation and adaptation cannot be overstated, ensuring that baler strapping remains a cornerstone of the modern supply chain.