The Innovative Solution for Securing Your Cargo: Woven Lashing Strap

Introduction

In today’s fast-paced world, the demand for safe and efficient cargo transportation is increasing. From heavy machinery to delicate electronics, the challenge of securing goods during transit has always been a top priority for logistics and transportation professionals. Enter the woven lashing strap, a revolutionary solution that offers the perfect combination of strength, durability, and flexibility. This article delves into the world of woven lashing straps, exploring their unique features, benefits, and applications.

The Evolution of Woven Lashing Straps

The traditional method of securing cargo has been through the use of steel chains, ropes, and wire. However, these materials often present challenges such as rust, weight, and difficulty in handling. Woven lashing straps were developed to address these issues, offering a lightweight yet strong alternative to traditional methods. Made from high-quality polyester or nylon, woven lashing straps are designed to withstand the harshest environments and provide reliable cargo security.

Features and Benefits of Woven Lashing Straps

1. Strength and Durability: Woven lashing straps are designed to handle heavy loads without compromising on strength or durability. They are made from high-quality materials that can withstand extreme temperatures, UV exposure, and abrasion, ensuring that your cargo remains secure during transportation.

2. Lightweight: Compared to steel chains and wire ropes, woven lashing straps are significantly lighter, making them easier to handle and store. This weight reduction not only reduces labor costs but also contributes to fuel efficiency and reduced carbon emissions.

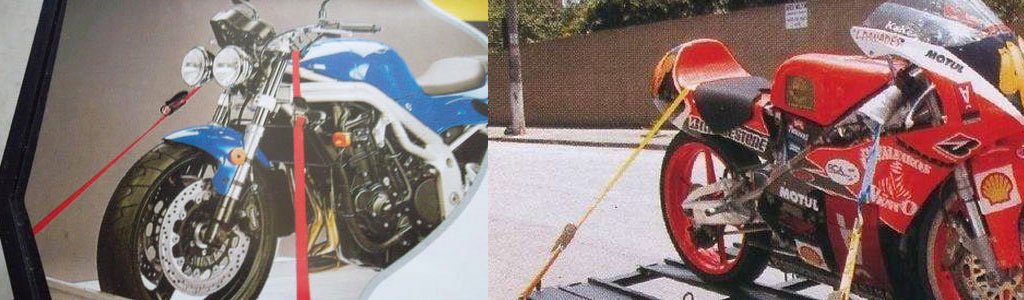

3. Flexibility: Woven lashing straps are highly flexible, allowing them to be easily adjusted to fit various cargo sizes and shapes. This flexibility ensures a snug and secure fit, reducing the risk of cargo shifting during transit.

4. Safety: Woven lashing straps are designed with safety in mind. The material is non-conductive, reducing the risk of electrical hazards during transportation. Additionally, the smooth surface of the strap reduces the risk of abrasion and damage to cargo.

5. Versatility: Woven lashing straps can be used in various industries and applications, from securing construction materials to truss up heavy machinery. Their versatility makes them an ideal choice for businesses seeking a reliable and adaptable cargo securing solution.

Applications of Woven Lashing Straps

1. Transportation: Woven lashing straps are widely used in the transportation industry to secure cargo on trucks, trains, and ships. Their strength and flexibility ensure that goods remain secure during transit, reducing the risk of damage and loss.

2. Construction: In the construction industry, woven lashing straps are used to secure building materials, such as steel beams and concrete blocks. Their lightweight and flexibility make them ideal for use in tight spaces and on high-rise structures.

3. Agriculture: Farmers and agricultural workers rely on woven lashing straps to secure hay bales, bags of grain, and other agricultural products during transportation. The straps' strength and flexibility ensure that these valuable goods arrive at their destination safely.

4. Shipping and Logistics: Woven lashing straps are a popular choice for shipping and logistics companies, who need a reliable and efficient way to secure their cargo during transit. The straps' versatility and durability make them an ideal solution for businesses seeking to optimize their supply chain operations.

Conclusion

Woven lashing straps have revolutionized the way we secure cargo during transportation. With their strength, durability, flexibility, and versatility, they offer a reliable and efficient solution for businesses in various industries. As the demand for safe and efficient cargo transportation continues to grow, woven lashing straps will undoubtedly remain at the forefront of cargo securing solutions.