The Rise of Heavy Duty Composite Strapping: A New Generation in Packaging Solutions

Introduction

The world of packaging has been evolving rapidly in recent years, with the demand for more efficient, sustainable, and cost-effective solutions. One such innovation that has gained significant traction in the packaging industry is heavy duty composite strapping. With its unique combination of strength, flexibility, and durability, heavy duty composite strapping has become an attractive alternative to traditional steel and plastic strapping options. This article will explore the features, benefits, and applications of heavy duty composite strapping, as well as the reasons behind its growing popularity in the packaging sector.

Features and Benefits of Heavy Duty Composite Strapping

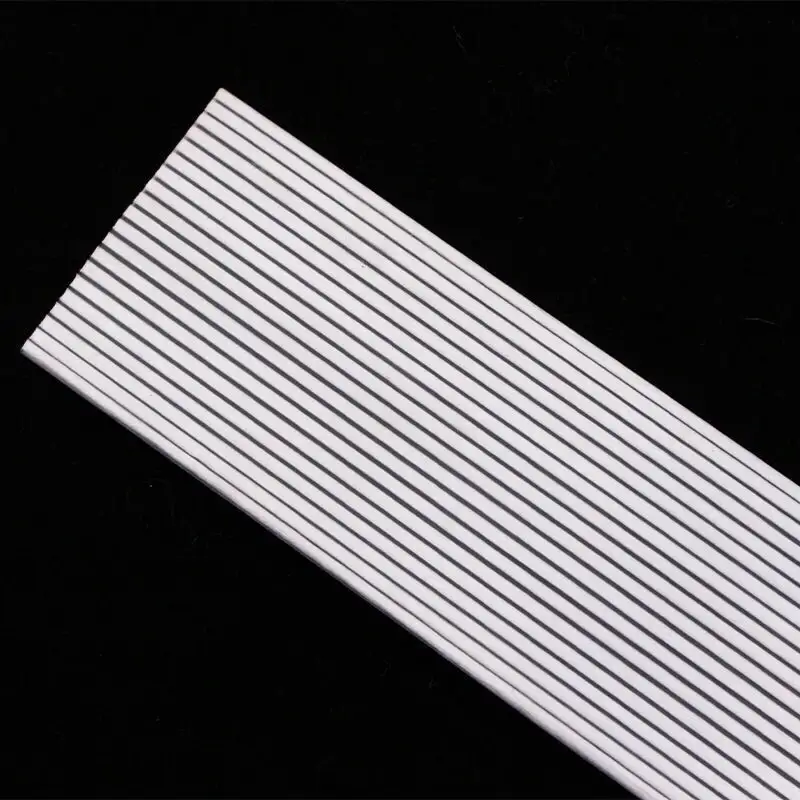

Heavy duty composite strapping is a type of strapping material that is made from a combination of high-strength polyester and polypropylene fibers. This unique composition gives it several advantages over traditional steel and plastic strapping options:

1. Strength and Durability: Heavy duty composite strapping is designed to withstand high loads and is capable of securing even the heaviest and most bulky cargo. Its high tensile strength makes it an ideal choice for applications where security and stability are paramount.

2. Flexibility: Unlike steel strapping, which is rigid and inflexible, heavy duty composite strapping is designed to be highly flexible. This flexibility allows it to conform to the shape of the cargo being secured, reducing the risk of damage during transportation.

3. Lightweight: Composite strapping is significantly lighter than steel strapping, making it easier to handle and reducing transportation costs. This weight advantage also makes it ideal for use in industries where weight is a critical factor, such as aerospace and automotive.

4. Sustainability: Heavy duty composite strapping is a more environmentally friendly option than traditional steel and plastic strapping. It is made from recyclable materials and can be easily disposed of at the end of its lifecycle.

5. Cost-Effective: Heavy duty composite strapping offers a cost-effective solution compared to traditional steel and plastic strapping options. Its longer lifespan, lower maintenance costs, and reduced transportation costs all contribute to its overall cost-effectiveness.

Applications of Heavy Duty Composite Strapping

Heavy duty composite strapping is widely used in a variety of industries, including:

1. Logistics and Transportation: Heavy duty composite strapping is commonly used to secure cargo during transportation, providing a safe and secure solution for a wide range of products.

2. Manufacturing: Composite strapping is used in manufacturing processes to secure raw materials and finished products, ensuring that they are protected during storage and transportation.

3. Construction: Heavy duty composite strapping is used in the construction industry to secure building materials and equipment, making it an essential tool for safe and efficient construction practices.

4. Agriculture: Composite strapping is used in the agricultural sector to secure hay bales and other large, bulky loads, ensuring that they are secure during transportation.

Conclusion

Heavy duty composite strapping is a versatile and innovative packaging solution that offers a range of benefits over traditional steel and plastic strapping options. Its strength, flexibility, lightweight, sustainability, and cost-effectiveness make it an attractive choice for a wide range of industries. As the demand for more efficient and sustainable packaging solutions continues to grow, heavy duty composite strapping is poised to become an even more prominent player in the packaging sector.