The Role and Significance of Baler Press Straps in Modern Packaging and Logistics

In the rapidly evolving world of packaging and logistics, the humble baler press strap often goes unnoticed. However, its role in ensuring the safety, efficiency, and cost-effectiveness of the entire supply chain cannot be overstated. Baler press straps, as their name suggests, are integral components of baling presses, machines that compress loose materials into dense, manageable bundles for easier handling and storage.

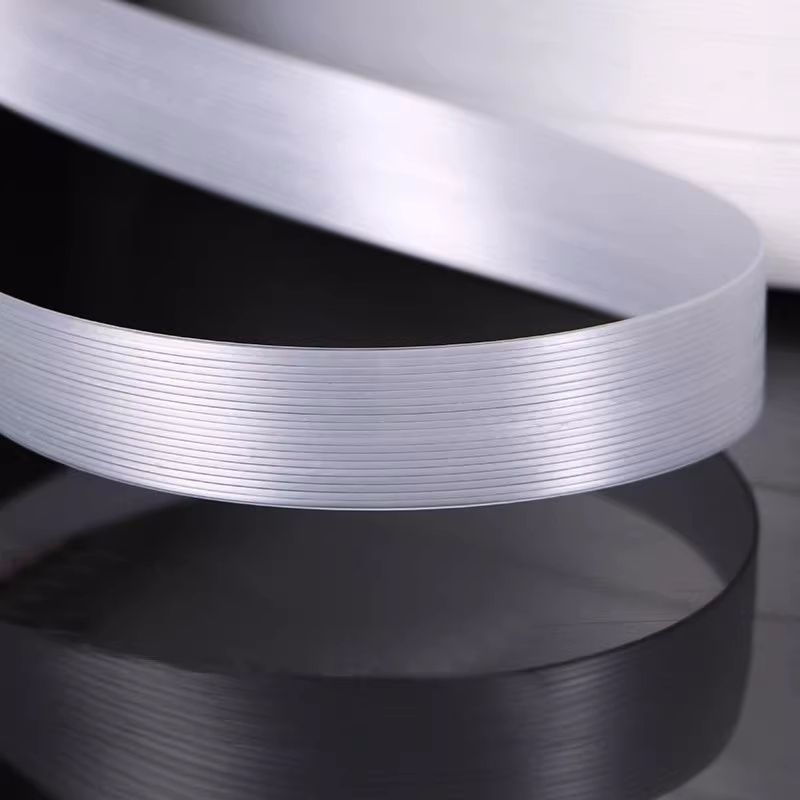

The basic function of a baler press strap is to secure the compressed material, ensuring it remains intact during transportation and storage. These straps are typically made of durable materials such as polypropylene or polyester, which provide the necessary tensile strength to hold even the heaviest loads securely.

The significance of baler press straps lies in their ability to optimize the packaging process. By securely binding the compressed material, they reduce the risk of damage or spillage, which can lead to costly losses. Furthermore, the compact bundles created by baler presses, with the help of the straps, occupy less space, making storage and transportation more efficient.

In the logistics industry, efficiency is key. Baler press straps contribute significantly to this by reducing the time and effort required for loading and unloading. The compact bundles created by baler presses are easier to handle, reducing the need for heavy lifting equipment or manual labor. This not only saves on labor costs but also reduces the risk of injuries to workers.

The durability of baler press straps is another crucial factor that makes them indispensable in packaging and logistics. These straps are designed to withstand the rigors of the supply chain, from the compression process itself to the rigors of transportation. Even in extreme conditions, such as high temperatures or humidity, baler press straps maintain their integrity, ensuring the safety of the contents.

Another important aspect of baler press straps is their recyclability. With the increasing focus on environmental sustainability, the ability to reuse or recycle packaging materials has become a significant consideration. Many baler press straps are made from recyclable materials, and they can often be recycled or reused after their initial use. This reduces the overall environmental impact of the packaging process.

In addition to their practical benefits, baler press straps also play a role in enhancing the professional image of a company. By ensuring that products are securely packaged and transported, these straps contribute to a perception of quality and reliability. This, in turn, can help to build trust with customers and enhance brand reputation.

However, it is important to note that not all baler press straps are created equal. The choice of the right strap depends on the specific application and the requirements of the material being compressed. For example, heavier materials may require straps with higher tensile strength, while straps used in outdoor environments may need to be resistant to UV rays or moisture.

Innovations in baler press strap technology are also helping to push the boundaries of packaging and logistics. New materials and designs are being developed that offer improved strength, durability, and recyclability. These advancements are enabling companies to achieve greater levels of efficiency and sustainability in their packaging and logistics operations.

In conclusion, baler press straps play a crucial role in modern packaging and logistics. Their ability to securely bind compressed material, optimize packaging processes, and enhance efficiency makes them indispensable in the supply chain. As companies continue to seek ways to improve their packaging and logistics operations, the importance of baler press straps is likely to increase even further.