The Role of Composite Cord Strapping in Australian Logistics Transportation

In the vast and dynamic landscape of Australian logistics, where diverse modes of transportation—including sea, air, and land—converge to meet the demands of a globalized economy, innovative packaging and securing solutions play a pivotal role. Among these, composite cord strapping stands out as a versatile and reliable tool that enhances the safety, efficiency, and cost-effectiveness of cargo handling. This article delves into the significance of composite cord strapping in the Australian logistics transportation sector, highlighting its unique features, applications, and the benefits it brings to the industry.

Introduction to Composite Cord Strapping

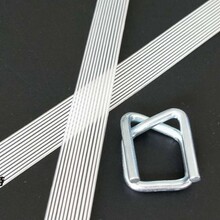

Composite cord strapping, a modern alternative to traditional steel banding, is a high-performance material designed for securing heavy and irregularly shaped loads. It combines the strength and durability of synthetic fibers with the flexibility and lightweight nature of plastic, resulting in a product that is safer, stronger, and more economical than its steel counterpart. The material is typically made from polyester or polypropylene fibers, reinforced with a plastic coating that enhances its resistance to weather conditions and load shifting.

Key Features of Composite Cord Strapping

1.Strength and Durability: Composite cord strapping boasts exceptional tensile strength, making it ideal for securing heavy loads without compromising on safety. Its durability ensures that the strapping remains intact even under extreme conditions, such as rough handling or exposure to harsh weather.

2.Lightweight and Flexible: Compared to steel banding, composite cord strapping is significantly lighter, reducing transportation costs and making it easier to handle. Its flexibility allows for better conformity to irregularly shaped loads, ensuring a tighter and more secure fit.

3.Weather Resistance: The plastic coating on composite cord strapping provides excellent resistance to moisture, UV radiation, and temperature fluctuations. This ensures that the strapping maintains its integrity throughout the transportation process, regardless of the environmental conditions.

4.Non-Corrosive and Non-Damaging: Unlike steel banding, composite cord strapping does not rust or cause damage to the cargo or packaging materials. This is particularly important for sensitive or fragile goods that require extra care during transportation.

Applications in Australian Logistics

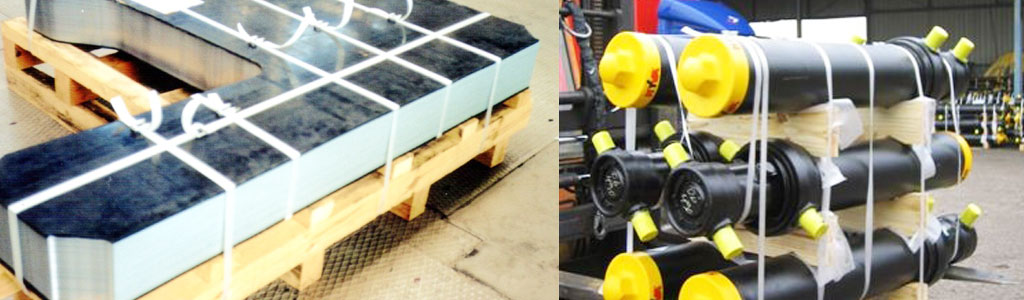

1.Maritime Transportation: Australia's maritime industry relies heavily on composite cord strapping to secure containers and heavy cargo on ships. Its strength and durability ensure that loads remain secure during long sea voyages, while its lightweight nature reduces the overall weight of the shipment, thereby lowering transportation costs.

2.Air Freight: For high-value and time-sensitive goods, air freight is often the preferred mode of transportation. Composite cord strapping's ability to securely fasten loads without adding significant weight makes it an ideal choice for air cargo packaging. Its resistance to weather conditions and load shifting ensures that goods arrive safely and in pristine condition.

3.Land Transportation: In the vast landmass of Australia, road and rail transportation play a crucial role in connecting remote regions and major cities. Composite cord strapping is widely used in securing loads on trucks and trains, ensuring that they remain stable during long journeys over bumpy roads and tracks.

4.Industrial Applications: The versatility of composite cord strapping extends to various industrial settings, including lumberyards, manufacturing facilities, and warehouses. It is used to bundle and secure raw materials, finished products, and even machinery, ensuring that they are safely transported and stored.

Benefits to the Logistics Industry

1.Cost Savings: The lightweight nature of composite cord strapping reduces transportation costs, as less fuel is required to move lighter loads. Additionally, its durability means that it can be reused multiple times, further reducing packaging expenses.

2.Increased Safety: The strength and flexibility of composite cord strapping ensure that loads are securely fastened, reducing the risk of accidents and damage during transportation. This, in turn, protects both the cargo and the personnel involved in the logistics process.

3.Environmental Sustainability: As a recyclable material, composite cord strapping contributes to a more sustainable logistics industry. Its reduced weight also means that less fuel is consumed during transportation, reducing carbon emissions and environmental impact.

Conclusion

In conclusion, composite cord strapping has emerged as a vital tool in the Australian logistics transportation sector. Its unique combination of strength, durability, flexibility, and lightweight nature makes it an ideal solution for securing heavy and irregularly shaped loads across various modes of transportation. As the logistics industry continues to evolve and adapt to the demands of a globalized economy, composite cord strapping will play an increasingly important role in ensuring the safe, efficient, and cost-effective movement of goods across Australia and beyond.