The Versatility and Innovation of Composite Straps in Modern Applications

In today's rapidly evolving technological landscape, composite straps have emerged as a game-changing material, revolutionizing various industries with their unique properties and versatility. From automotive components to sports equipment, composite straps have demonstrated their ability to outperform traditional materials while offering significant advantages in terms of strength, durability, and weight reduction.

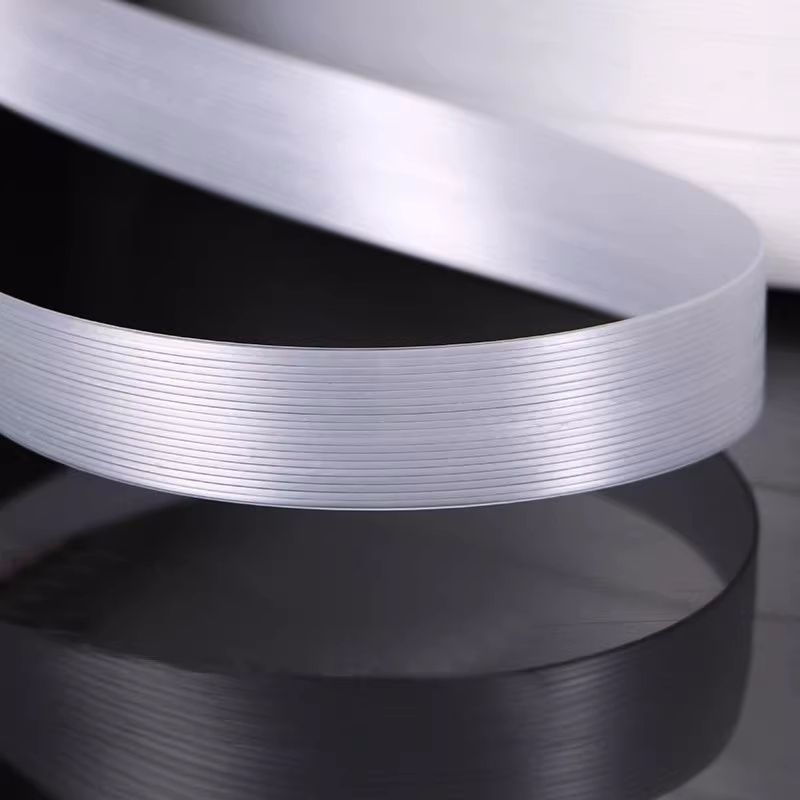

The Basics of Composite Straps

Composite straps are typically composed of two or more materials that are combined to create a new material with superior properties. These straps often feature a reinforcement material, such as fiberglass, carbon fiber, or Kevlar, embedded within a matrix material like epoxy or polyester resin. This combination results in a material that is lightweight, yet incredibly strong and resilient.

The reinforcement material provides the necessary strength and stiffness, while the matrix material holds the reinforcement in place and distributes loads evenly throughout the composite. The result is a strap that can withstand high tensile forces and repeated cycles of stress without suffering from fatigue or breakage.

Applications in the Automotive Industry

The automotive industry has been a major beneficiary of the development of composite straps. In recent years, composite straps have been used in a variety of applications, from body panels and chassis components to suspension systems and brake lines. The lightweight nature of composite straps allows for significant reductions in vehicle weight, which translates into improved fuel efficiency and reduced emissions.

Additionally, the high strength-to-weight ratio of composite straps means that they can be used to replace heavier metal components, further reducing weight while maintaining or exceeding the structural integrity of the vehicle. This has led to the development of more efficient and environmentally friendly vehicles that are capable of achieving higher speeds and better handling characteristics.

Advancements in Sports Equipment

Composite straps have also found their way into the world of sports equipment, where they are used to create innovative and high-performance products. In cycling, composite straps are used in bike frames and components to create lightweight and stiff frames that are capable of handling the rigors of high-speed racing. The durability and resilience of composite straps also make them ideal for use in ski poles, snowboarding bindings, and other winter sports equipment.

In addition to their use in traditional sports equipment, composite straps are also being explored for use in emerging technologies like exoskeletons and wearable robotics. These devices rely on lightweight yet strong materials to provide support and assistance to the wearer, and composite straps are a promising candidate for meeting these demands.

The Future of Composite Straps

As technology continues to advance, the applications for composite straps are likely to expand even further. Researchers are constantly exploring new reinforcement materials and matrix combinations to create stronger, lighter, and more durable composites. This will enable composite straps to be used in even more demanding applications, from aerospace components to medical implants.

In addition to material advancements, the development of new manufacturing techniques will also play a crucial role in the future of composite straps. Techniques like additive manufacturing (3D printing) and automated fiber placement are making it easier and more cost-effective to produce complex composite components. This will open up new opportunities for using composite straps in a wider range of applications.

Conclusion

Composite straps have become a valuable tool in the toolbox of modern engineering and design. Their unique properties and versatility have enabled them to be used in a wide range of applications, from automotive components to sports equipment. As technology continues to advance, the potential applications for composite straps are likely to expand even further, making them an essential material for the future of innovation and progress.