The Versatility and Significance of Lashing Woven Straps in Heavy-Duty Cargo Packaging

In the intricate world of logistics and transportation, where safety and efficiency are paramount, the use of specialized equipment and materials is crucial. Among these, lashing woven straps have emerged as indispensable tools for securing heavy-duty cargo during transit. These sturdy, yet flexible, bindings play a pivotal role in ensuring that valuable and potentially hazardous loads remain intact and stable, mitigating the risks associated with shifting or collapse during long journeys over varying terrains. This article delves into the unique characteristics, applications, and significance of lashing woven straps in heavy-duty cargo packaging.

Introduction to Lashing Woven Straps

Lashing woven straps, also known as cargo lashing straps or tie-down straps, are engineered with strength, durability, and adaptability in mind. Made from high-tensile fibers such as polyester, nylon, or polypropylene, they are woven into a dense, interlaced pattern that enhances their resistance to abrasion and tearing. The woven construction not only imparts exceptional load-bearing capacity but also ensures even distribution of tension across the strap's width, minimizing the risk of stress concentration and subsequent failure.

Unique Characteristics

1.High Tensile Strength: Lashing woven straps are capable of supporting immense loads, making them ideal for securing everything from construction materials to industrial machinery. Their strength-to-weight ratio is exceptional, allowing for lightweight yet robust solutions.

2.Flexibility and Adaptability: The woven design offers exceptional flexibility, allowing the straps to conform to the contours of irregularly shaped cargo. This feature is particularly useful when dealing with bulky or awkwardly dimensioned loads.

3.Weather Resistance: Most modern lashing woven straps are treated with UV inhibitors and water-resistant coatings, ensuring they maintain their integrity even under extreme weather conditions.

4.Easy Handling and Reusability: Designed with user-friendly features like soft edges and quick-release buckles, these straps are easy to apply, adjust, and remove. Their durability ensures they can be reused multiple times, reducing costs and waste.

Applications in Heavy-Duty Cargo Packaging

1.Maritime Shipping: On ocean-going vessels, where cargo is exposed to rolling waves and strong winds, lashing woven straps are essential for securing containers, pallets, and breakbulk cargo. They help prevent shifting, which could lead to damage or even catastrophic accidents.

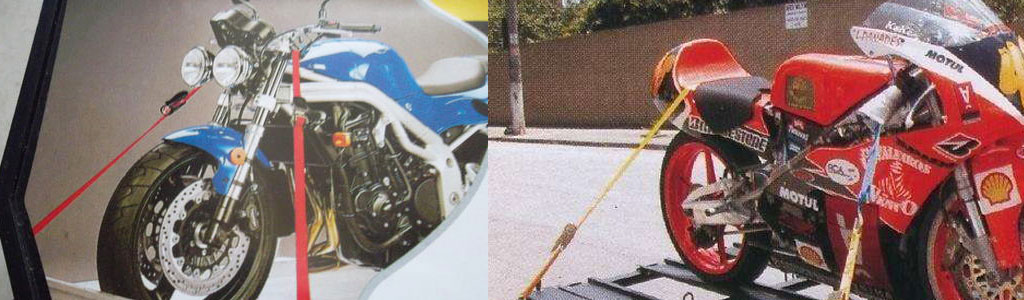

2.Road and Rail Transportation: In trucks and trains carrying heavy machinery, construction equipment, or agricultural produce, lashing woven straps secure loads to the vehicle's floor or to each other, ensuring stability during transport. This minimizes the risk of accidents caused by unsecured cargo.

3.Air Freight: Although less common due to weight restrictions, lashing woven straps are still used in air cargo operations where heavy, bulky items need to be safely secured within aircraft holds.

4.Storage and Warehousing: Within warehouses and storage facilities, these straps are used to stabilize stacks of pallets or to secure large, heavy items during temporary storage, preventing collapse and ensuring smooth inventory management.

5.Specialized Industries: In industries like mining, oil and gas exploration, and aerospace, where equipment is both heavy and sensitive, lashing woven straps are tailored to meet specific requirements, ensuring safe and secure transportation of critical components.

Significance and Benefits

-Increased Safety: The primary benefit of using lashing woven straps is the enhanced safety they provide. By securing cargo effectively, they prevent accidents caused by shifting loads, protecting both cargo and personnel.

-Cost Savings: By reducing the risk of damage during transit, these straps help minimize costly repairs or replacements. Their reusability further reduces long-term costs.

-Efficiency: Quick and easy to apply, lashing woven straps streamline the loading and unloading process, improving operational efficiency.

-Environmental Sustainability: Reusable nature of these straps promotes a more sustainable approach to cargo packaging, reducing waste and minimizing the environmental impact of transportation.

Conclusion

In conclusion, lashing woven straps are indispensable tools in the realm of heavy-duty cargo packaging. Their unique combination of strength, flexibility, and adaptability makes them the go-to solution for securing a wide range of loads across various modes of transportation. By ensuring the safe and efficient transport of heavy-duty cargo, these straps contribute significantly to the smooth functioning of global supply chains, protecting valuable assets, minimizing risks, and promoting sustainability. As the logistics industry continues to evolve, the importance of innovative and reliable cargo securing solutions like lashing woven straps will undoubtedly grow.