What is Composite Cord Strapping?

I. Introduction to Composite Cord Strapping

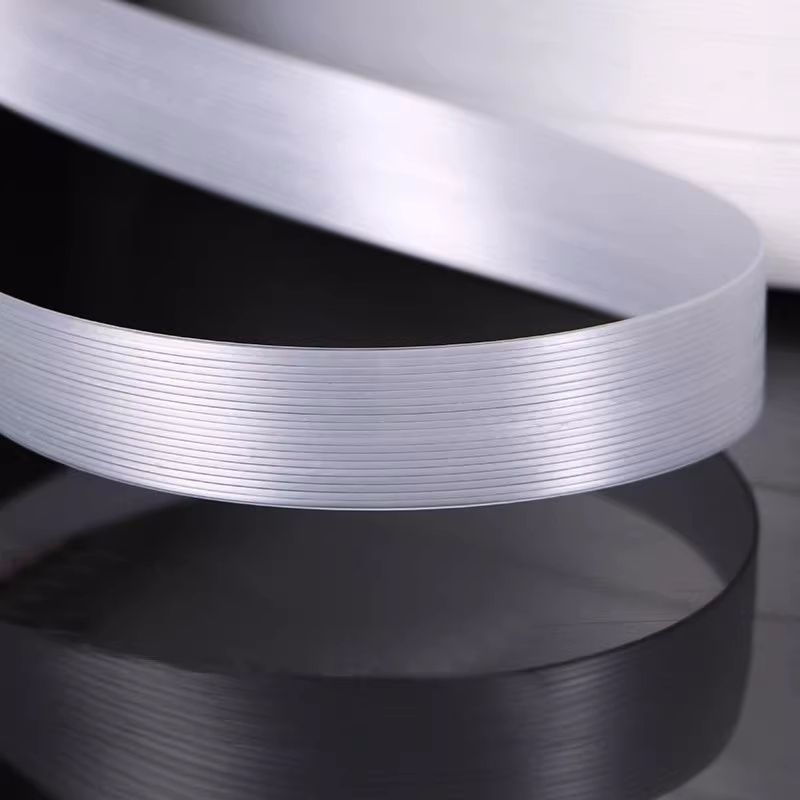

Composite cord strapping is a type of strapping material that combines the strength and flexibility of corded fibers with the durability and reliability of plastic strapping. This innovative packaging solution offers a versatile and cost-effective alternative to traditional steel strapping, making it ideal for securing heavy loads in various industries, including shipping, construction, and manufacturing. In this article, we will explore the features, benefits, applications, and best practices of composite cord strapping, highlighting its importance in modern packaging operations.

II. Features of Composite Cord Strapping

Composite cord strapping is composed of high-tenacity polyester cords encased in a polymer coating, providing a strong and resilient strapping material that can withstand high tension and loads. The combination of corded fibers and plastic coating offers excellent shock absorption, allowing the strapping to stretch and recover during transport without breaking. Additionally, composite cord strapping is lightweight, flexible, and easy to handle, making it a user-friendly alternative to steel strapping. The weather-resistant properties of composite cord strapping make it suitable for both indoor and outdoor applications, providing reliable performance in various environmental conditions.

III. Benefits of Composite Cord Strapping

1. Strength and Durability: Composite cord strapping offers superior strength and durability compared to traditional strapping materials, such as steel or nylon. The high-tensile strength of the polyester cords combined with the protective polymer coating ensures secure and reliable load containment during transit.

2. Safety: Composite cord strapping is safer to handle than steel strapping, as it does not have sharp edges or potential for recoil. This reduces the risk of injuries for packaging personnel and enhances workplace safety.

3. Cost-Effectiveness: Composite cord strapping is a cost-effective solution for securing heavy loads, as it is more affordable than steel strapping and requires minimal maintenance. The lightweight nature of composite cord strapping also helps reduce shipping costs by decreasing overall package weight.

4. Versatility: Composite cord strapping can be used for a wide range of applications, including bundling, palletizing, and securing irregularly shaped loads. Its flexibility and elongation properties make it suitable for securing loads that may shift or settle during transport.

5. Environmentally Friendly: Composite cord strapping is recyclable and eco-friendly, making it a sustainable packaging option for businesses looking to reduce their environmental impact.

IV. Applications of Composite Cord Strapping

Composite cord strapping is used in various industries for securing and stabilizing heavy loads during transportation and storage. Some common applications of composite cord strapping include:

1. Shipping and Logistics: Composite cord strapping is widely used in the shipping and logistics industry for securing palletized loads, crates, and containers. Its high tensile strength and shock-absorbing properties make it ideal for long-distance transportation.

2. Construction: Composite cord strapping is used in the construction industry for securing building materials, such as lumber, pipes, and steel beams. Its weather-resistant properties make it suitable for outdoor applications on construction sites.

3. Manufacturing: Composite cord strapping is utilized in manufacturing facilities for bundling and securing products, equipment, and machinery. Its flexibility and durability make it an essential tool for optimizing packaging and storage processes.

4. Agriculture: Composite cord strapping is used in the agriculture industry for securing bales of hay, straw, and other agricultural products. Its resistance to UV rays and moisture makes it ideal for outdoor storage and transport.

V. Best Practices for Using Composite Cord Strapping

To ensure the optimal performance and safety of composite cord strapping, it is essential to follow best practices when using this packaging material. Some key best practices include:

1. Selecting the Right Size and Type: Choose the appropriate width and strength of composite cord strapping based on the weight and dimensions of the load being secured. Consider the application and environmental conditions to determine the best type of strapping for the job.

2. Proper Tensioning: Ensure that the strapping is tensioned correctly to securely hold the load in place without causing damage. Over-tensioning can lead to premature failure, while under-tensioning may result in load shifting during transport.

3. Inspecting for Damage: Regularly inspect composite cord strapping for signs of wear, fraying, or damage. Replace any damaged strapping immediately to prevent failures and ensure load security.

4. Using Appropriate Tools: Use the right tools and equipment, such as tensioners and sealers, to properly secure and fasten composite cord strapping. Avoid using makeshift tools that may compromise the integrity of the strapping.

5. Storage and Handling: Store composite cord strapping in a clean, dry environment away from direct sunlight and extreme temperatures. Properly coil and protect the strapping to prevent tangling and damage.

VI. Conclusion

Composite cord strapping is a versatile and reliable packaging material that offers numerous benefits for securing heavy loads in various industries. Its strength, durability, safety, cost-effectiveness, and environmental sustainability make it an attractive alternative to traditional strapping materials. By understanding the features, benefits,as well as best practices, enterprises can maximize the use of composite ropes to improve packaging and transportation efficiency, ensure the safety of goods, and reduce the risk of damage. By selecting appropriate specifications and types, properly tensioning, regularly inspecting for damage, using appropriate tools and equipment, and properly storing and handling composite ropes, businesses can ensure their effectiveness and reliability during transportation and storage.

Ultimately, Composite cord strapping as an innovative packaging material provides businesses with a sustainable and efficient solution that helps optimize transportation and storage processes. By fully understanding its characteristics, advantages, and best practices, enterprises can fully utilize the potential of composite cord strapping, improve their supply chain management and packaging transportation efficiency, and thus achieve higher customer satisfaction and competitive advantage.